Product Lists

Hot Product

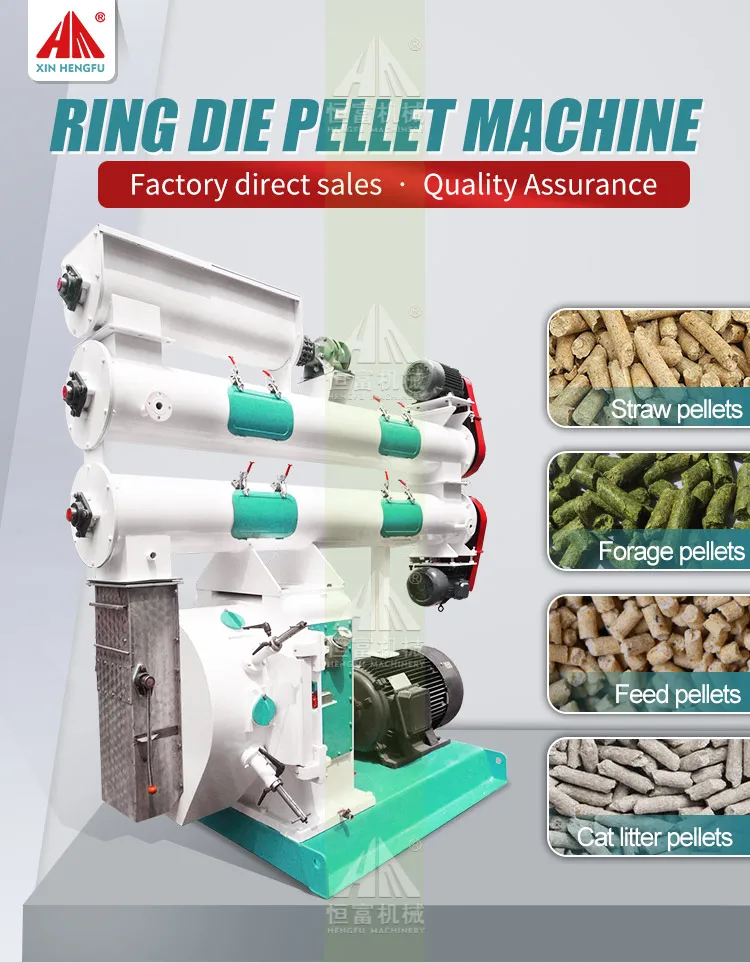

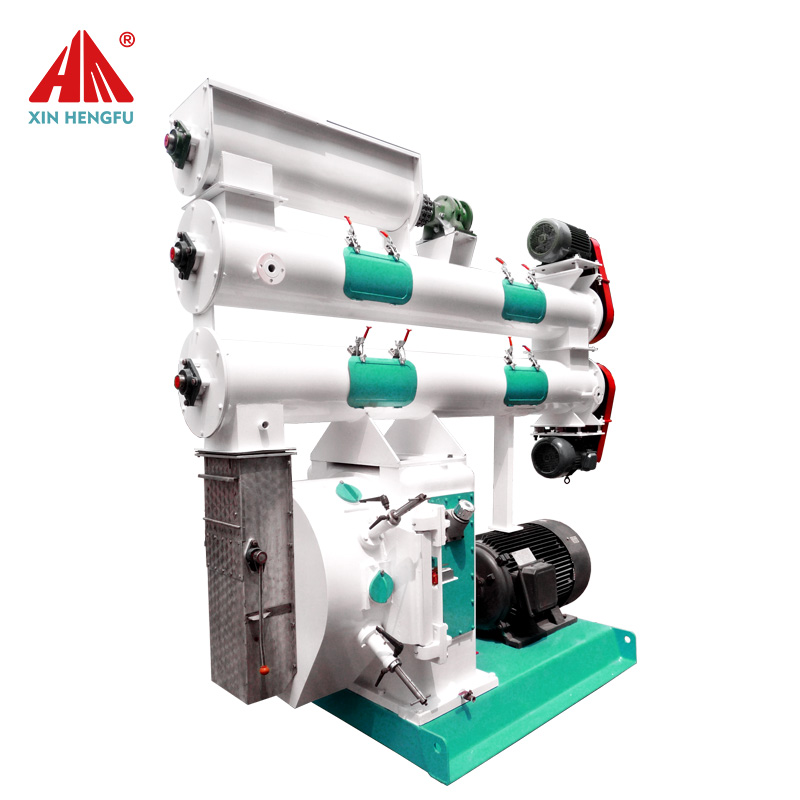

SZLH400 ring die pellet machine

High Efficiency Pellet Making Machine Prouduce All of Animal Pellet Feed

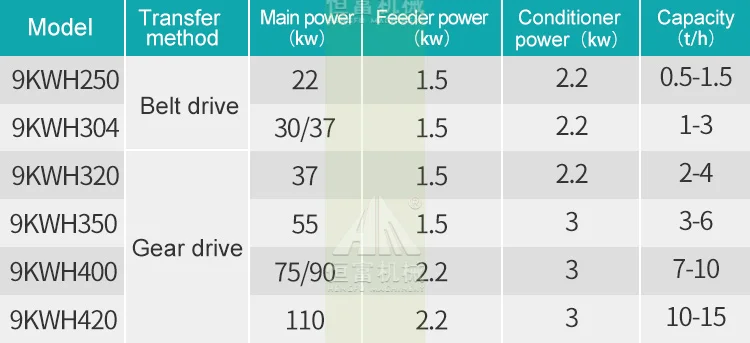

Ring die pellet press machine is driven by belt or gear type ,the advantages as follows:

1.Belt drive :simple structure ,low nosiy ,suitalbe for small and medium farm or feed mill.

2.Gear drive:advanced design ,high capacity ,long lifetime ,suitable for medium and large farm or feed mill.

3.It can used seperately or connect with grinder mixer cooling machine and other accessory equipments,thus it is a completely animal feed production line .

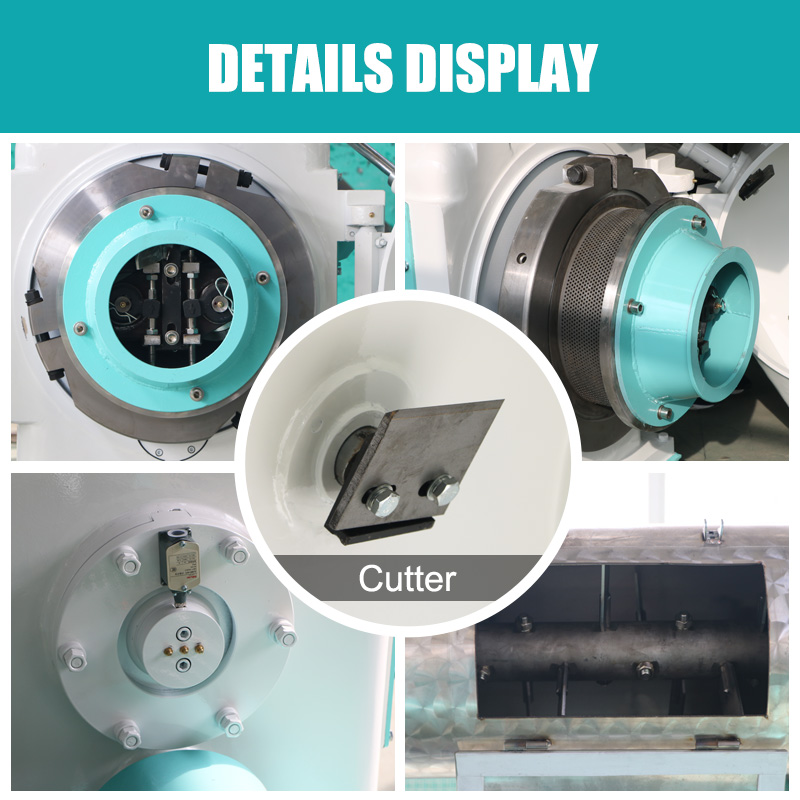

The pellet mill machine working principle is after quenched and tempered of the material through the feed hopper by gravity,

centrifugal force generated by the rotation ring mold and the role of the riving knife cut evenly feeding ring touch the two suppression area, touch and pressure stick in the ring under the action of strong compression , the material is compacted gradually, squeeze ring touch the die hole and the hole is formed in the mold, because the material between the mold extruded rod is continuous, so after molding material from the die hole is discharged continuously columnar, then cut to the desired length by a cutter particles into the next process (cooling, crusher).

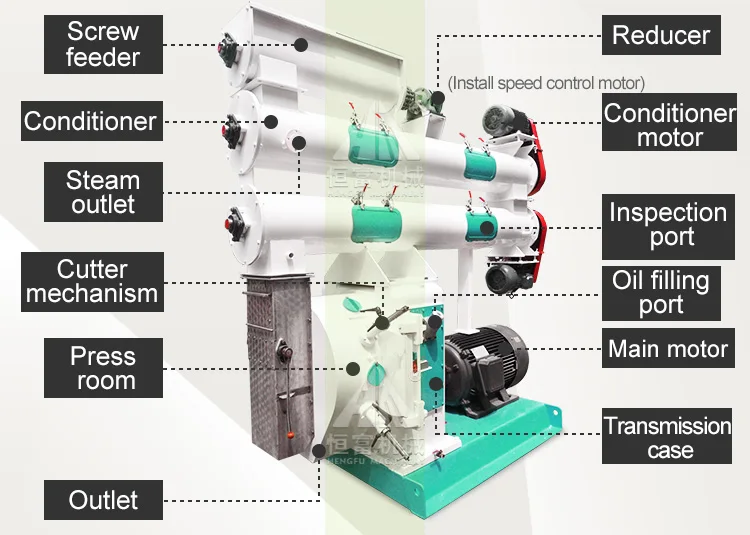

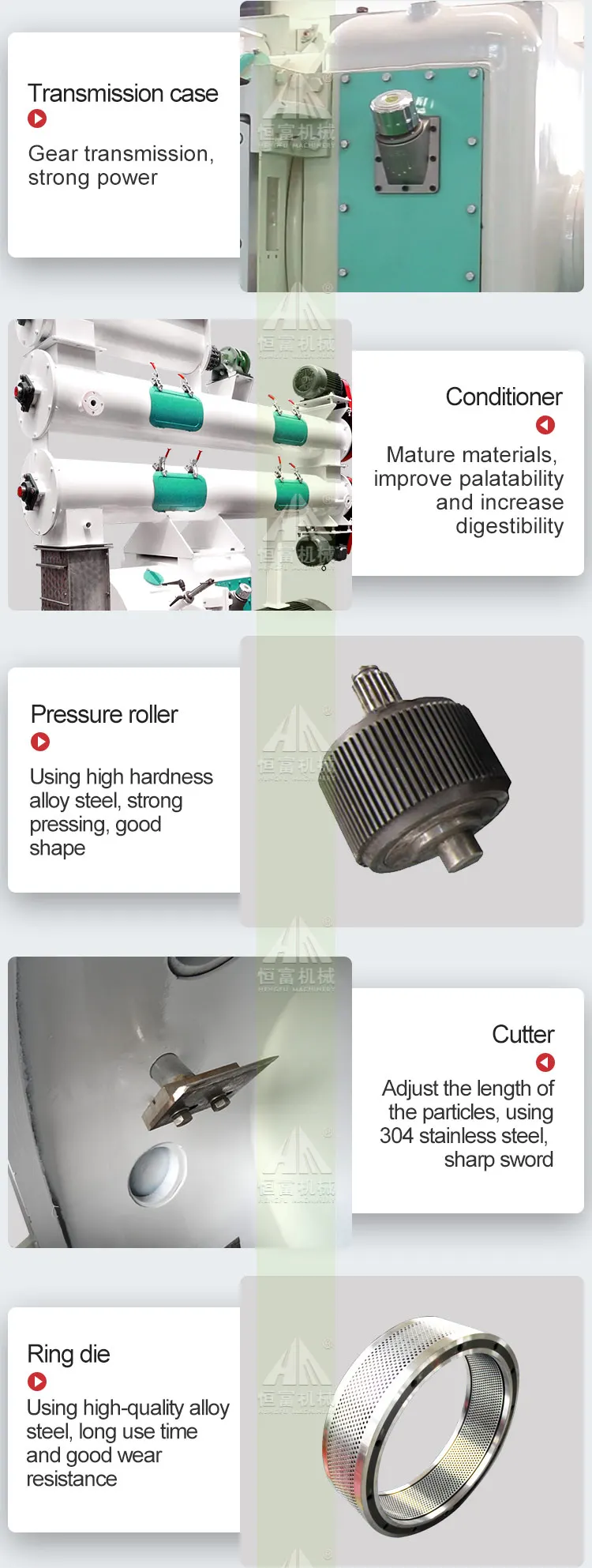

Structural features

1) Ring mold made of high quality stainless steel with precision machining, application of vacuum heat treatment process, a small hole finish high, long service life.

2) Forged alloy steel shaft, has good strength and toughness.

3) Cast steel hollow shaft with a large flywheel pulley effect, so that work can be smoothly pellet mill, low noise, almost no vibration.

4) Feeder, conditioner, granulating cavity are using stainless steel, inlaid carbide cutter blade, durable.

5) The lubrication line running through the Rollers bearings can be readily obtained and good lubrication, to ensure that they operate in a better condition.

6) Equipped with a compact, convenient ring moldliftingmechanism.

The main spare parts are roller assemble and pellet mill mould , The material of mould is super alloy steel and stainless steel,in this proposal we equiped with stainless steel.Surface hardness can reach to 53-59HRC,the lifetime is 8000 ton.

The material of roller is high-carbon alloy steel,surface hardness can reach to above 80 degree SHORE.

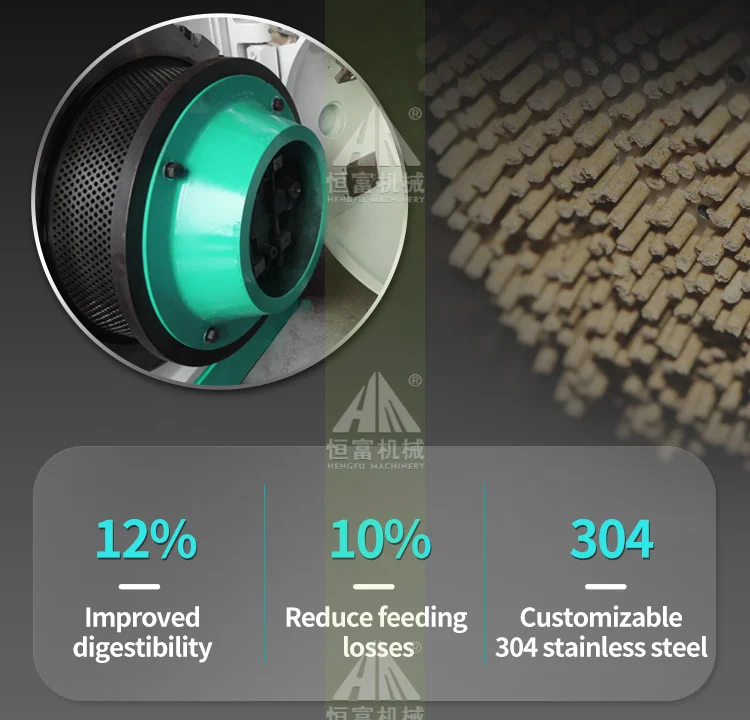

Now more and more feed mill also add conditioner to produce good quality pellets feed ,to sell at good price.The advantage of conditioner as follows:

make starch gelatinization in feed,improve product quality and digestibility.

The feed after conditoner has strong fluidity and adhesiveness,which is beneficial to feed forming,can increase the density and water resistance,reduce the powder rate ,improve the quality of the pellets.

The feed after conditioner can be more soft,lubrication,reduce the friction heat and the wear of ring die ,roller,save energy,ultimately improve the productivity of the granulator.Reduce maintance costs and extend ring mould and roller life time.

How to Mainentence pellet mill:

Routine maintenance

1)Filling oil regularly to ensure that the machines work in good lubrication.

2)Periodically clear the magnet on iron impurities.

3)Always check all the fasteners, magnets, feeding cleaner and all safety

4)Full protection devices to ensure reliable and are in working condition.

5)Regularly check ring mold, pressure roller, cutter, the scraper blade, V-belts, wear

parts, and timely adjustment or replacement, make sure pellet mill normal, effective work.

6)Absolutely prevent foreign matter entering the ring mold, metal impurities embedded ring mold must be squeezed out or drilled from the hole, and in any case shall be welded to the ring mold treatment process

Finally ,how to start a pelletizer machine ,you can do as following steps:

Remove the feed trough.

Open the front door. Note: The front door should be transferred away from the ring mold cutter position.

Check the feeder,conditioner and ring cavity if there is iron and other debris.

Rotate the various activity sectors, guarantee not to bestuck.

Start conditioner and feeder, and then in the feeder at low speed stop.

Start the main motor, you should first check to make sure all moving parts pellet mill can operate freely. Secondly, we should check to make sure the ring mold rotates clockwise. Then adjust the two Rollers rotating ring mold to the surface and the inner surface of the contact, and in the role of ring mold, to turn non-genetically similar.

Note: Do not let the feed pellet mill under conditions without unnecessary idling, ring mold in order to avoid unnecessary damage and pressure stick.

Close the door, make sure the hopper feeder there is enough fodder, but a steady flow of balanced feeder. Exhaust steam condensate pipeline to prevent water droplets flow conditioner.

Before the re-placement of the feeding trough, with the amount of feed to operate the machine, so that feed through the entire system, remove the installation may be left in the machine's iron and other impurities. Feed metal impurities on the environment, and the whole pellet mill Rollers are harmful.

Above are main notes for pellet mill machine ,as for the price ,please kindly tell us your detail request ,we make suitable proposal for you.Now we have many different model pelletizer machine for sale in our warehouse ,please don't hesitate to send us inquiry.

If you are interested in our SZLH420 ring die pellet machine, there are some details to confirm:

1. What's your raw material?

2. The capacity per hour?

3. Is the pellet machine matched with production line? Any special requirements about the cross section size of die and discharge model?

Henan Hengfu Machinery Equipment CO. LTD., main products are premix feed plant, complete feed production line, concentrated feed production line, various feed plants and etc, Our company is specialized in premix feed plant, concentrated feed production line and different kinds of feed production lines, which is approved by many customers. Quality first and the credibility of the supremacy are our management principle, we are certain to provide superior service for you. If you have any needs, welcome contact me without hesitate.

|

|

|

|

|

| ring die pellet mill | flat die pellet mill | single shaft mixer | double shaft mixer | chaff cutter |

|

|

|

|

|

| pellet feed plant | feed mixer and grinder | hammer mill | feed grinder | drum mixer |

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)

![[field:title/]](/uploads/200429/1-200429155P5295.jpg)

![[field:title/]](/uploads/210320/1-210320111U4X1.jpg)