Product Lists

Hot Product

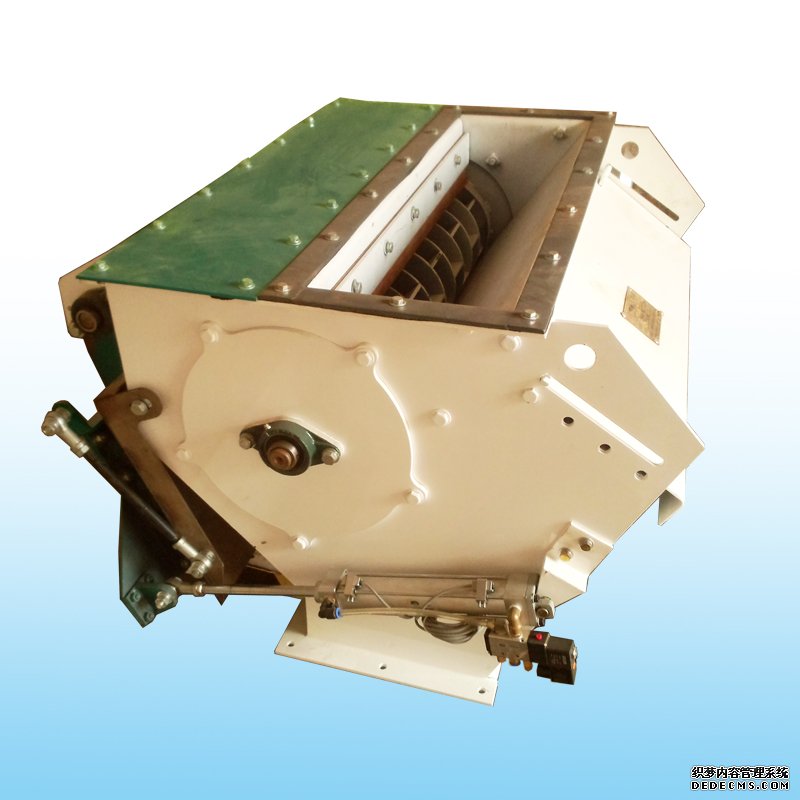

impeller feeder

Impeller feeder is a kind of feed equipment which is specially used together with water drop hammer mill in feed machinery.It is used to ensure the feeding speed of hammer mill is in the appropriate range.

Structure composition

Impeller feeder mainly consists of valve body, transmission shaft, blades and reducer, and the material is carbon steel.

Working principle

Impeller feeder is a feeding device combined with feed grinder,upper inner cavity of impeller rotor is divided into left and ring two chambers by baffle,upside of the right one has material inlet,material can come into the right chamber through the dripping plate,and then it can move from the right one to the left one with the rotation of the rotor.Rotation speed of rotor can be automatically controlled by controller, which make feeder feeding speed uniform and adjustable.Both sides of feeder shell are respectively installed with magnetic separation mechanism and inlet mechanism,which can remove magnetic impurities and supply air to hammer mill according to need while feeding,no need to specifically set magnetic device and air inlet mechanism.

Product features

1Whole trough is closed,suitable for feeding of non-fragile pellets and various powder materials.

2Rotating components and bearings are less,reliable and easy to maintain and operate,lower cost.

3Design of feeding and discharging mechanism is simple and practical,can carry out multi-point loading and discharge.

Operation flow

1Before starting to do routine inspection,check if there is impurities in the chassis, the most important thing is to see whether the hanger bearing is involved in high fiber impurities.

2 Material in the impeller feeder should be carried out a preliminary cleaning,such as using cylinder cleaning screen and conical powder screen remove large impurities,to ensure the normal operation of machine safely.

3Before operation feeder should be empty running, and then feeding.Material flow should be gradually increased and controlled in the appropriate range,not overloaded.

Packaging & Shipping

Company Information

Certifications:

Our Services

FAQ

Application scope

Impeller feeder is used to continuously move drying powdery material above the silo or small particles to the next device uniformly, it is a kind of quantitative feeding equipment. This feed machinery can be called star unloading valve, star unloader, rotary feeder.

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)

![[field:title/]](/uploads/200429/1-200429152913558.jpg)

![[field:title/]](/uploads/170317/1-1F31G55T9601.jpg)

![[field:title/]](/uploads/170317/1-1F31G54R0443.jpg)