Product Lists

Hot Product

9KLP flat die pellet machine

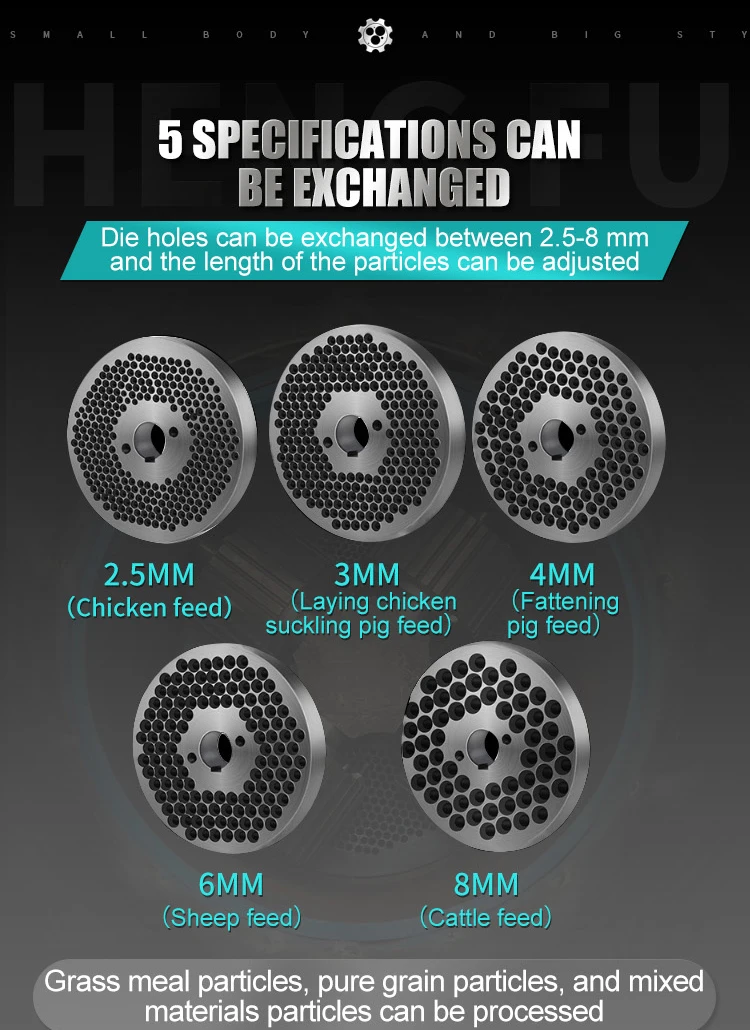

Pellet Mill, also known as a pellet press is a type of mill or machine press used to create pellets from powder material. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces.

Pellet Mill with flat die is an original machine for pellet burning and animal feed. This machine is equipped with high quality die and rollers and has advanced technology. For driving system we use double motor V-belt, which is of little space occupation, uniform stress, simple structure and easy operation. Users can change motor and die to meet the needs of different production capacities and specs, thereby obtains ideal technology and economy effect.

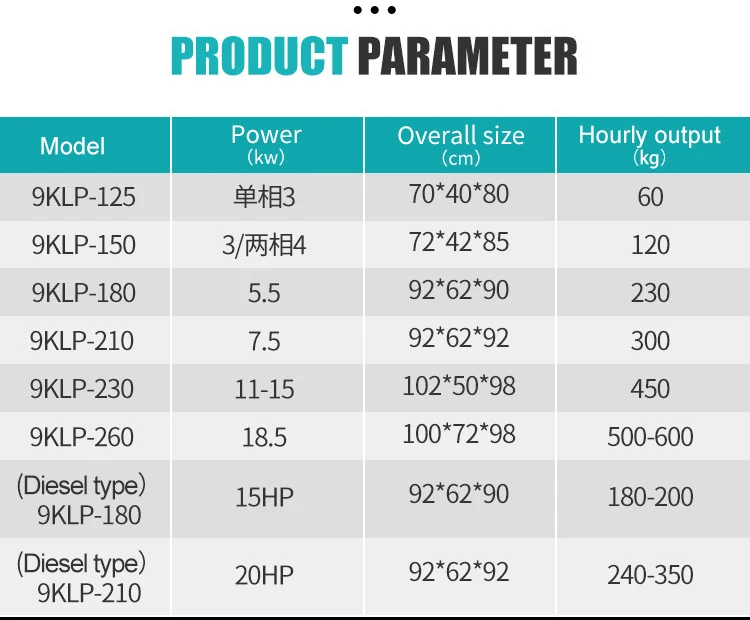

Electric Motor Pellet Mill:

The electrical pellet mill is the most widespread kind machine for electricity is everywhere in our daily life. If the working place and material resources are steady, a electrical pellet mill can totally meet your home processing .

Diesel Pellet Mill:

When you want to pelletize in the farms or orchards, electricity would be not convenient to use. Then, diesel motored pellet mills for home use are applicable. You just need to add diesel oil to the motor, and the machine will work efficiently and flexibly.

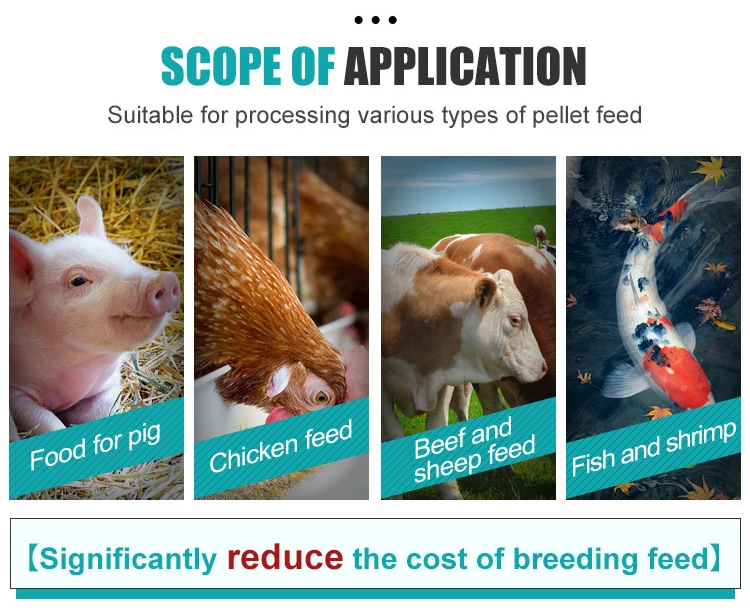

It’s applicable for all kinds of industry breeding and making waste organics of brewing, sugar, paper, medicine, tobacco industry into granulation.

Why choose us?

As a specialized pellet equipment supplier and manufacturer, our company has accumulated rich experience for over ten years. We dedicate to develop new technology for improving the efficiency of our products and providing you high quality pellet mill for sale. And we received good feed back from customers who have ever purchased our pellet mill for sale

Pre- and Post- Sale Service

A. Steady and timely supply of spare parts

B. We can timely settle customers’ problems in 24 hours.

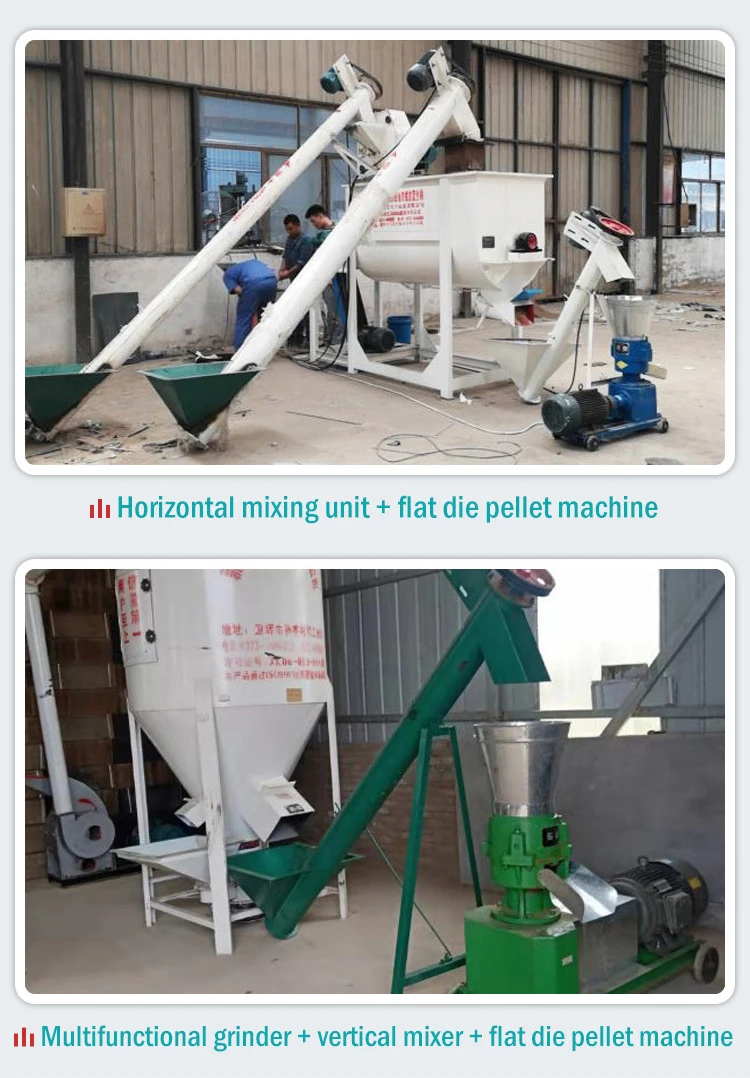

C, We can provide customers with services including cost analysis like production benefit analysis, consulting service, and relevant service of optimization and combination of small pellet complete set, etc.

D. Multilingual Instruction.

E. Incoming tests are allowed

F. Supplying with Europe Standard industrial plugs

G. Providing experiment sets for tests of different countries’ voltage and frequency.

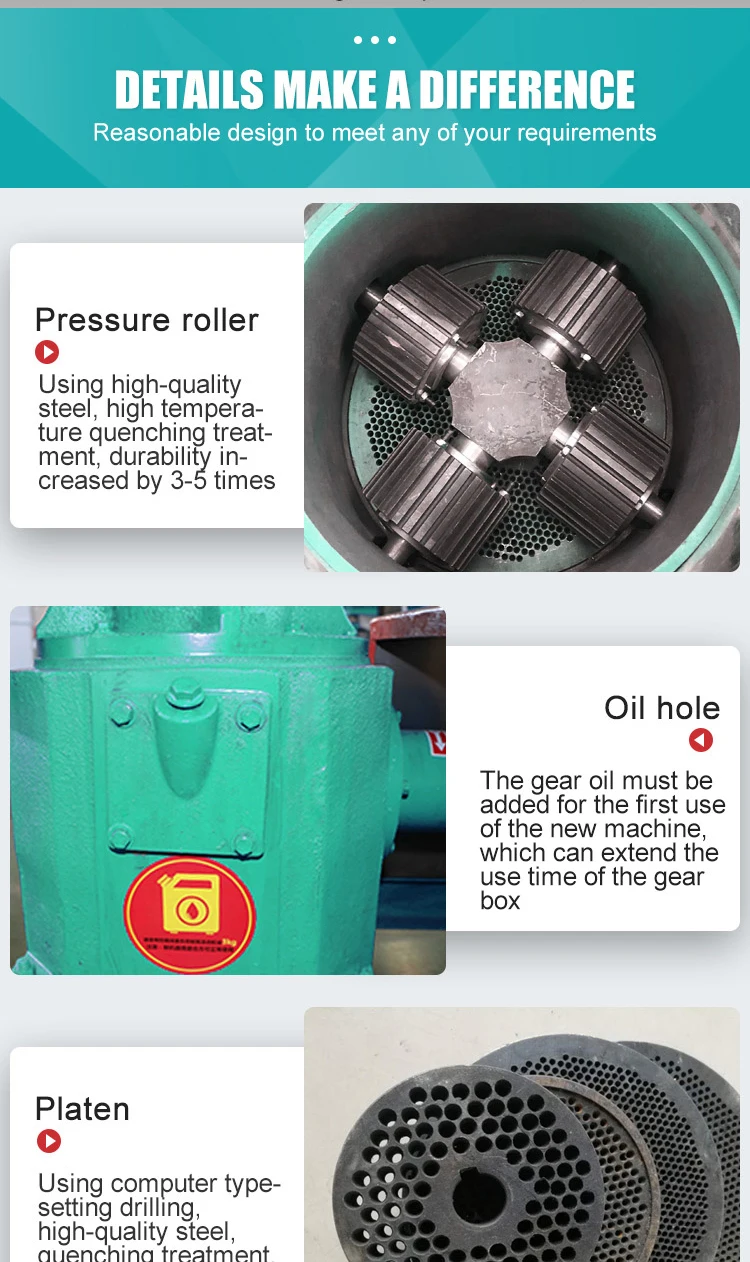

High efficiency, high productivity with low energy consumption.

Feeder sealing: Feed hopper and hopper adopts galvanized sheet, which can rust. And feed hopper uses the curling structure, while other manufacturers adopt soldering easy to crack.

Adopting the whole sheet metal crimping, pressure side structure, solid and reliable.

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)

![[field:title/]](/uploads/200429/1-2004291526192N.jpg)

![[field:title/]](/uploads/210320/1-210320111234405.jpg)

![[field:title/]](/uploads/210420/1-21042014292M22.jpg)