How to humidify the granule in the process of granulation

Author:Animal Feed Block Making Machine

updatetime:2017-05-12

Clicks:12

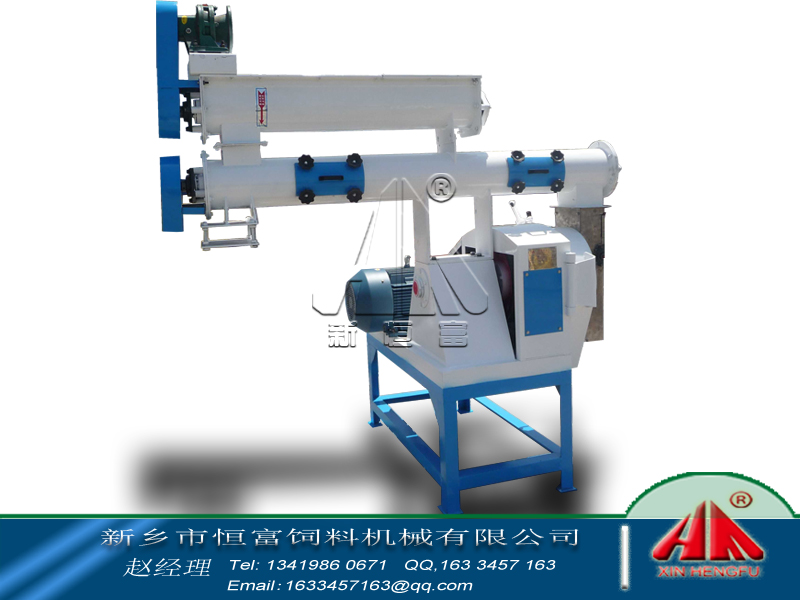

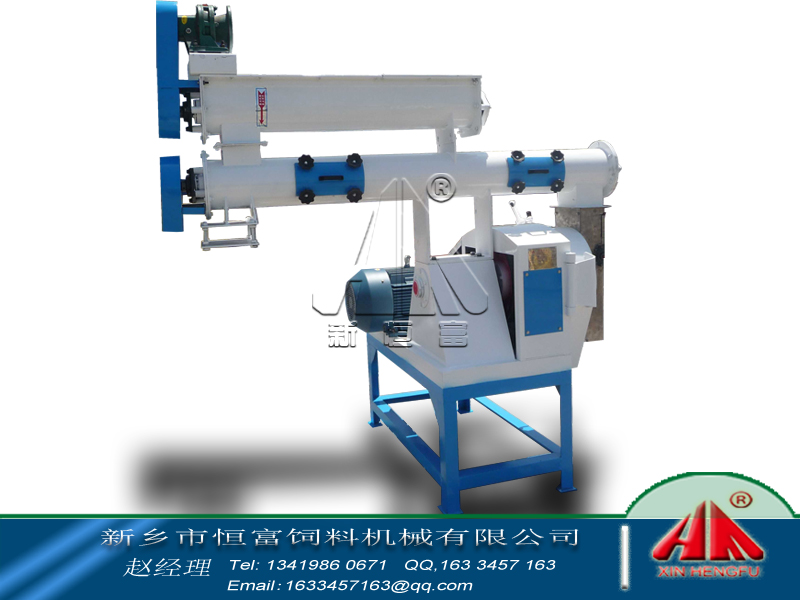

Palatability of pellet feed is good and the nutrition is balanced,it gets more and more farmers’welcoming in recent years.However,if the farmers purchase equipment themselves,they will inevitably encounter such problems,Hengfu animal feed machinery manufacturers today have a simple discussion on the granulation process of humidification.

Generally speaking,when talking about humidification of the granulator,naturally think of the steam conditioner,and the working principle is essentially the use of uniaxial welding staggered leaves,raised powder to be wet.It is well known that the main factors affecting the effect of powder molding are the humidity of the material.Hengfu machinery is designing the production process of the series of pellets and taking into consideration the maneuverability of the granulation process,it is usually designed to steam humidification and tap water humidification,the user only need to choose one according to the actual situation of granulation.Of course,the premise is to require the steam pressure of 0.2~0.4Mpa,thermometer 85 ~ 100 ℃,tap water pressure to spray is better,to ensure the powder wet,so that the pressure of the granules bright,neat incision,low rate.It is important to note that the steam pipe of the feed pellet mill conditioner barriel can be centrally installed on a drum for easy operation.SZLH 250 ring die pellet mill think the steam should enter the inter layer from the tangent position and the inter layer ejects the steam in the axial direction,mixed with the material more intense, tap water humidification is the same operation, the granulation effect is generally not too much different with the expected.

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)