Crushing and processing of cake feed

Author:Animal Feed Block Making Machine updatetime:2017-05-10 Clicks:12

In the processing of soybean cake,temperature control is the most important link.Too high or too low temperature will affect the protein content of soybean cake,and directly lead to the quality of the future cake and use effect.There is a gate or baffle in the bottom of hopper for common feed mill,such as processing soybean meal,first break soybean,maximum size after breaking should not exceed 40mtn;processing sweet potato vine,first chop the vine,length should not exceed 150 mm, adjusting the opening of gate or baffle can control the amount of feed,improve crushing quality and operating efficiency,to avoid overload.

Soybean cake and soybean meal as high protein cake feed,matching with a lot of corn, a small amount of fish meal is very suitable for livestock nutrition needs of amino acids.On the other hand, both soybean cake and soybean meal contain a certain amount of residual fat and oil,and the content of soybean oil and soybean meal is 5% to 10% and 1% to 2%.Therefore,when adding oil in the animal feed formula,use the soybean cake with less fat,or use soybean meal with more fat, because they have different amount of fat.But after the oil extract of the bean cake seasoned soybean cake, such as chickens, pigs etc.,ruminants can not be directly to feed,it needs to go through the steaming or drying process before feeding.

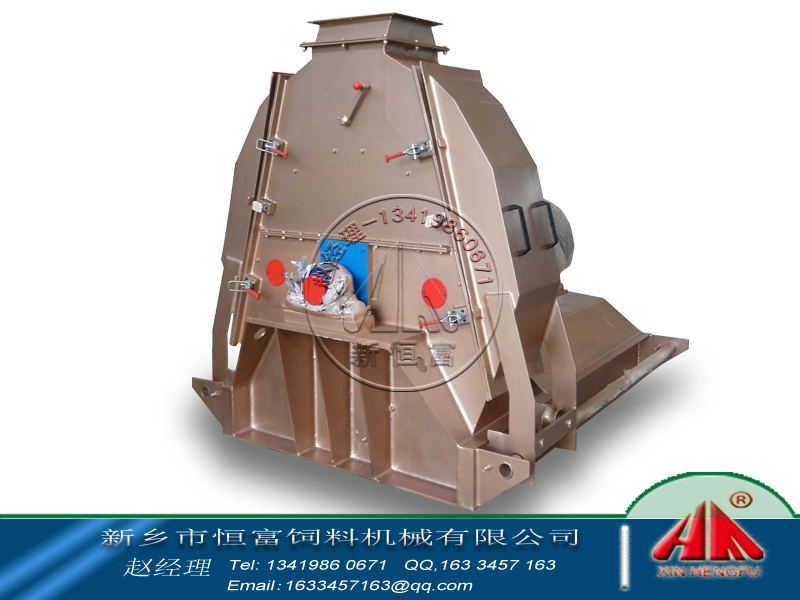

Hengfu complete aniamal feed plant according to the actual situation of the production of automatic feed mill,a certain extent to meet the farmers on the full demand for cake feed,use of international advanced technology, optimized hammer arrangement, special secondary crushing design,high precision balance test to ensure that the crusher does not move at the same time to avoid dust spills, noise is too large and other shortcomings,especially after the SFSP968*40 water drop hammer mill appear on the market,it’s widely welcomed by the feed, brewing, solvent and other industries.

![[field:title/]](/uploads/200429/1-200429152356308.jpg)

![[field:title/]](/uploads/200429/1-200429152252A1.jpg)

![[field:title/]](/uploads/200429/1-200429160330427.jpg)

![[field:title/]](/uploads/210607/1-21060G32R1B3.jpg)